Products PRODUCTS

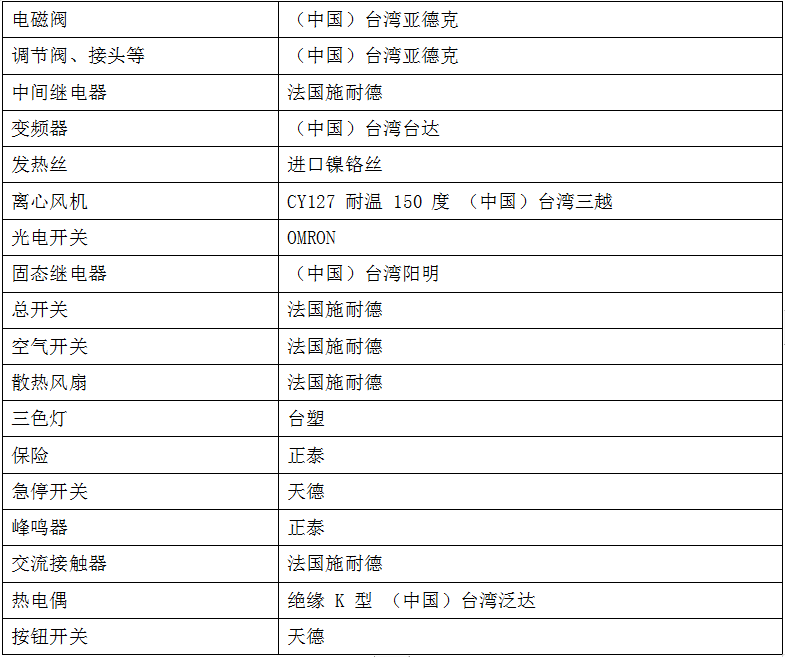

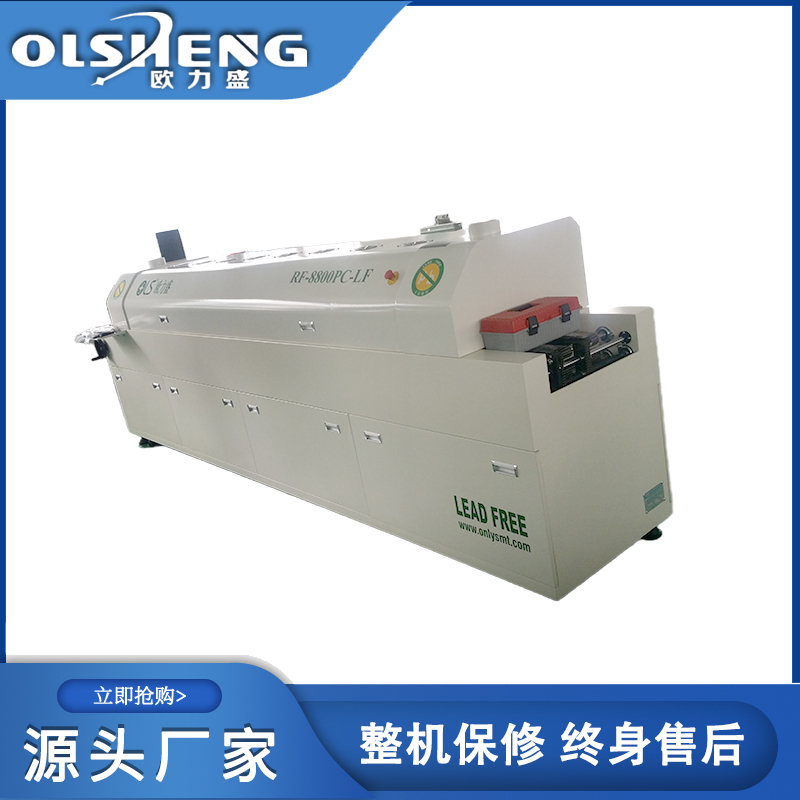

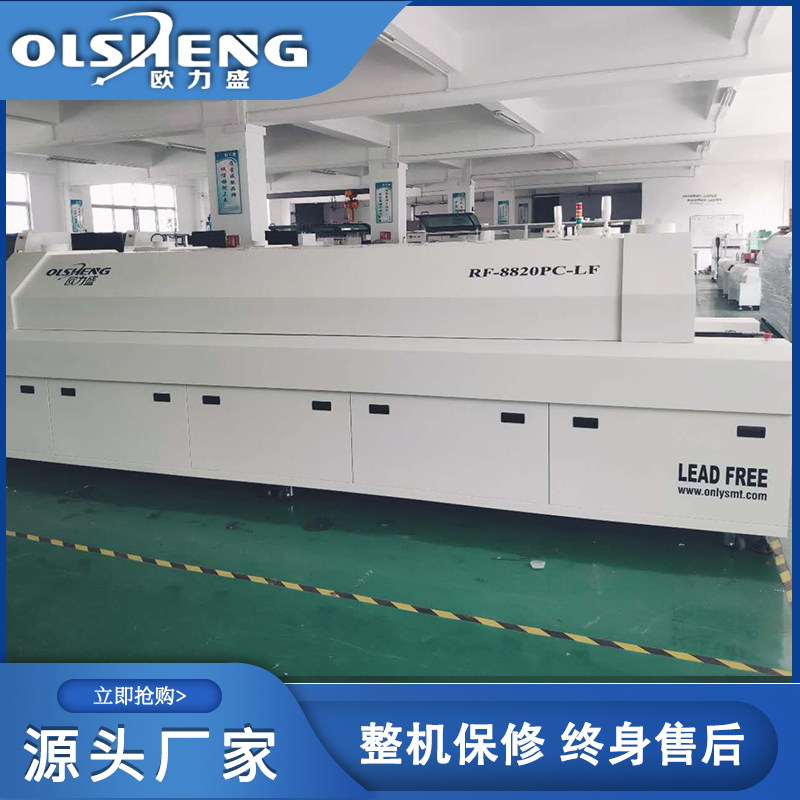

RF-8820PC-LF lead-free computer-controlled eight-temperature zone

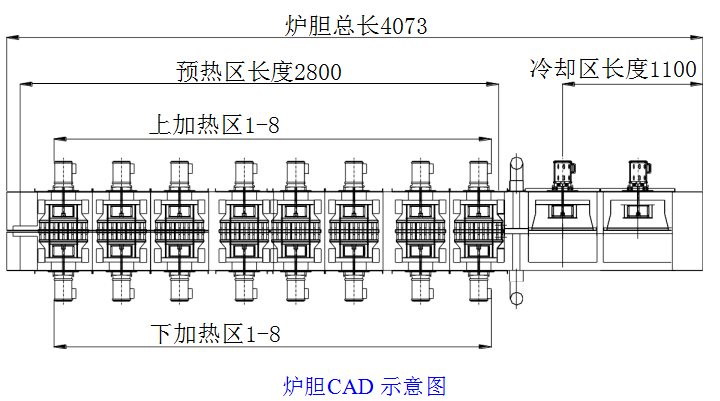

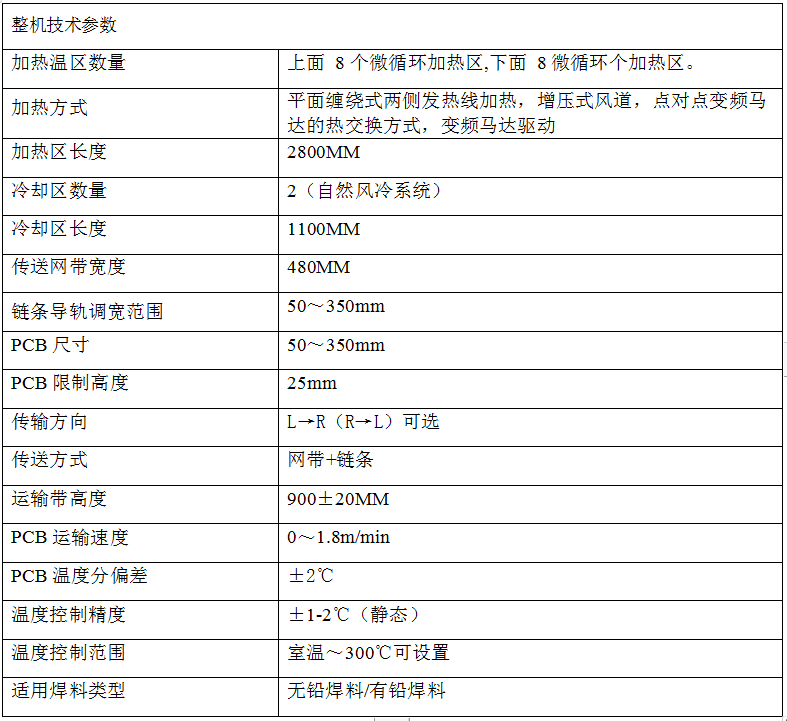

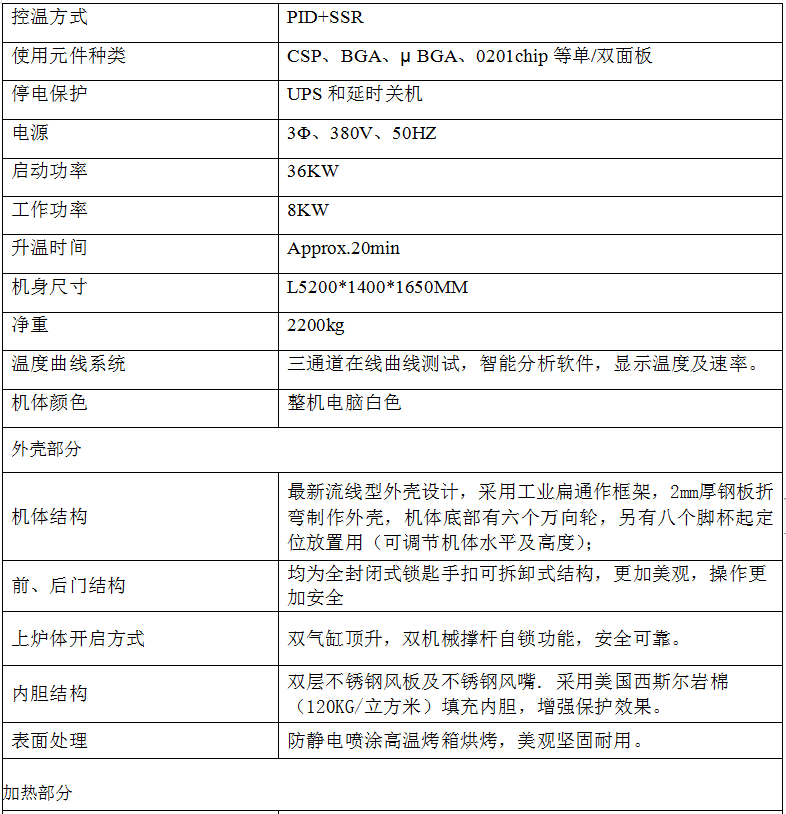

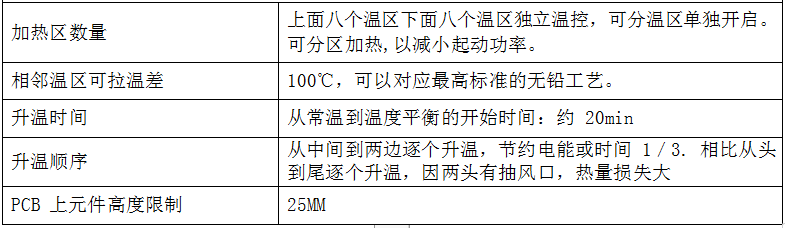

The adopted circulation technology divides the entire furnace chamber into 3232 independent plots. the PCB soldering is heated with a very high accuracy of the temperature profile, which is ideal for soldering components with a small space window for lead-free processes.

Upper and lower independent heating modules, independent hot air circulation, double soldering zone or triple soldering zone settings.

Modular design for each temperature zone, high-temperature-resistant long-shaft hot-air motors and high-heat nickel-chromium heating wires. From room temperature to constant temperature in less than 20 minutes.

Lead-free computer-controlled eight temperature zones micro-circulation hot air reflow soldering

Model: RF-8820PC-LF

Unique advanced long life heating system

1.Adopted circulation technology, the whole furnace chamber is divided into 3232 independent cells.PCB soldering is heated with very high accuracy of the temperature profile, very suitable for lead-free processes with small space window for component soldering.

2. Upper and lower independent heating module, independent hot air circulation, double or triple soldering zone setting.

3. Each temperature zone due to the use of modular design, high temperature resistant long axis hot air motor and high thermal energy nickel chrome heating wire. From room temperature to constant temperature in less than 20 minutes.

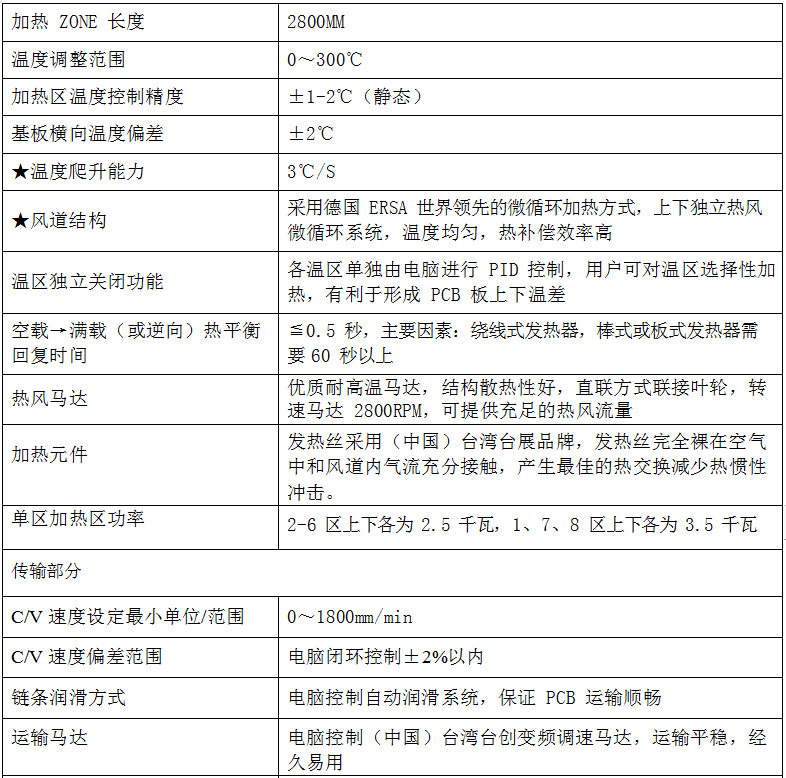

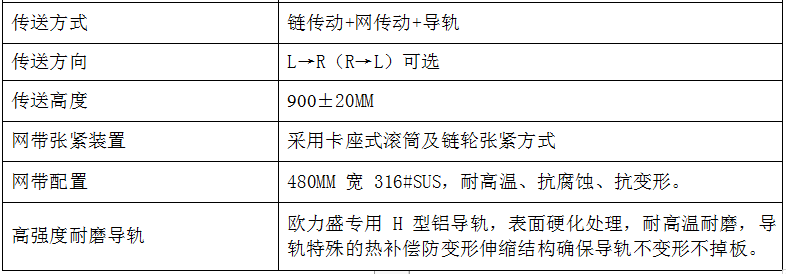

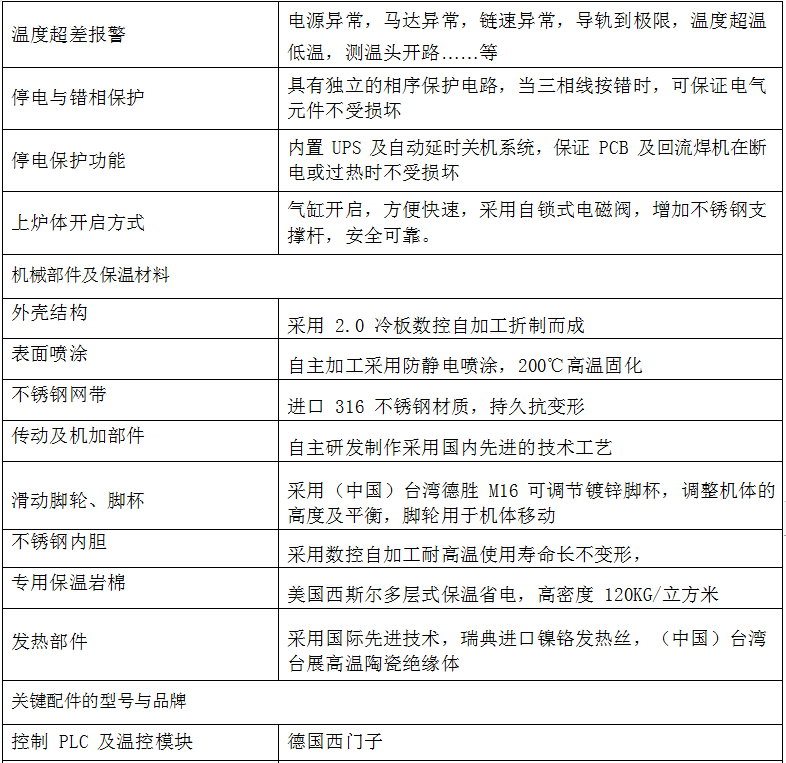

Reliable and smooth transmission system

1. Symmetrical double groove guide rail, high temperature resistance without deformation, small heat absorption. Standard chain, mesh chain synchronous parallel transport at the same speed, optional dual-guide transport system or central support system.

2. Widening adopts three sections synchronous widening structure, both ends are equipped with guide rail thermal expansion automatic extension device, which can effectively ensure the parallelism of the guide rail and prevent the occurrence of falling boards and jamming boards, free of cleaning and easy to adjust.

3. Computer-controlled automatic refuelling system can automatically refuel according to the transport speed and machine status, with adjustable flow rate.

4. The automatic width adjustment system adopts closed-loop PID control, which can automatically adjust to the required width according to the parameters inputted by the computer, and the degree can be up to 0.2mm.

5.UPS power failure protection function, to ensure that the PCB board can be normal output after a sudden power failure, without damage.

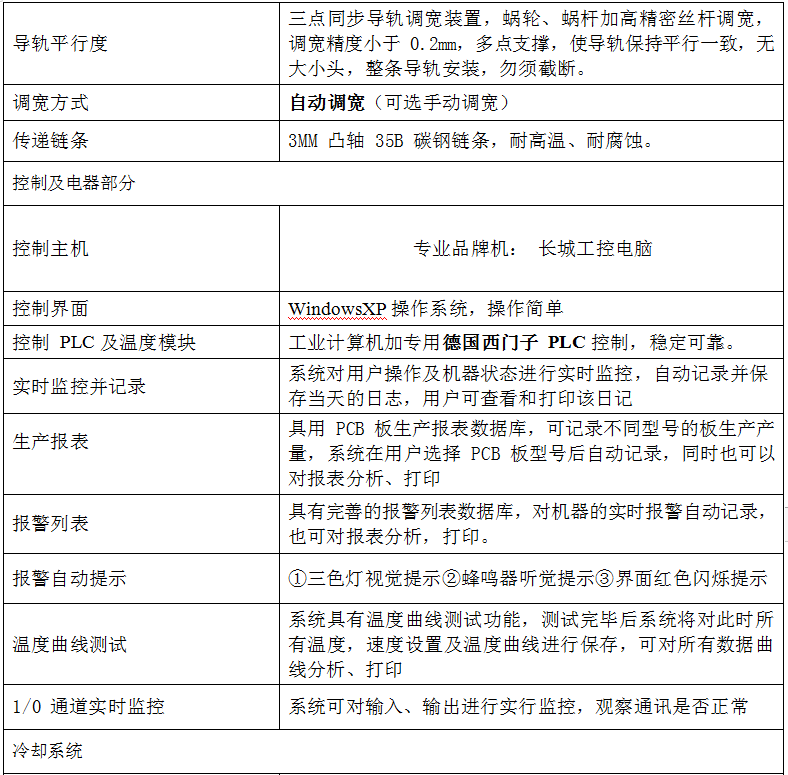

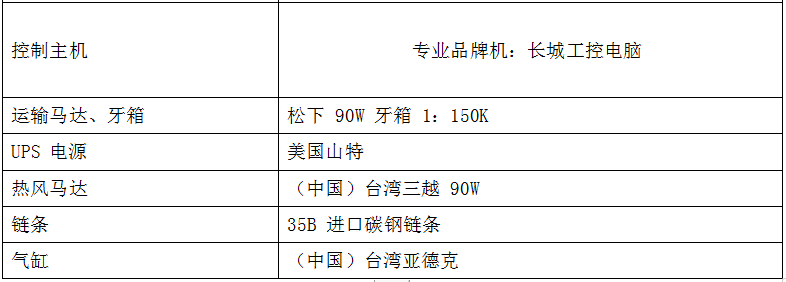

Stable and reliable electrical control system

1. The control system adopts PLC, and the upper computer adopts computer with genuine Windows XP operating system and 17 inch LCD monitor, which is stable and reliable.

2. The control software is powerful, with flexible process parameters control and temperature curve test function, Chinese and English operation interface can be switched at any time.

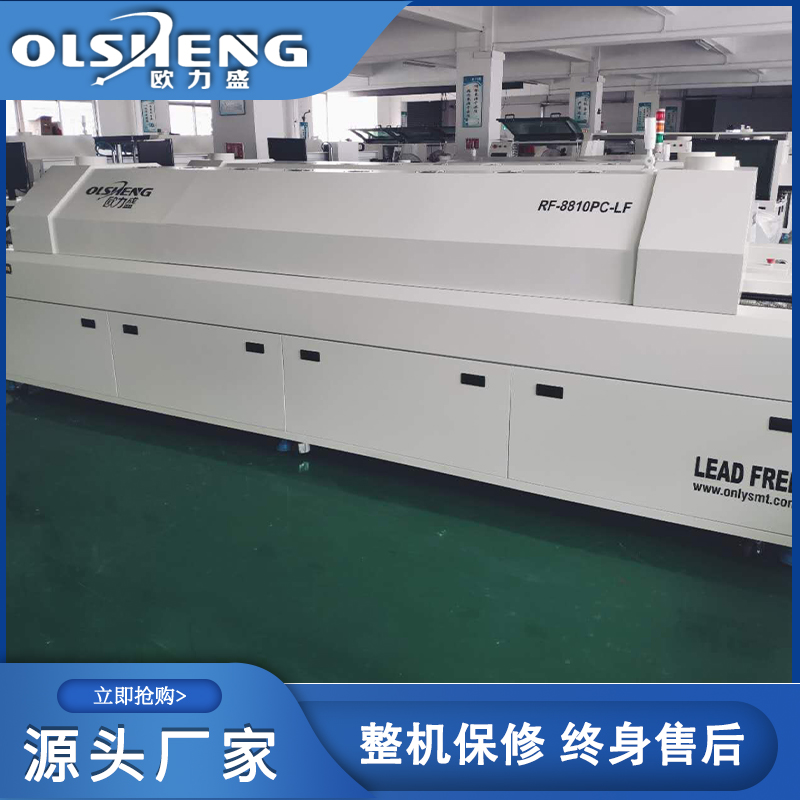

3. Adopt WOGO terminal; all important electrical components are imported brands, and all signal lines are shielded.

4. Temperature module self-tuning, cold end automatic compensation, temperature control in ± 1 ℃.

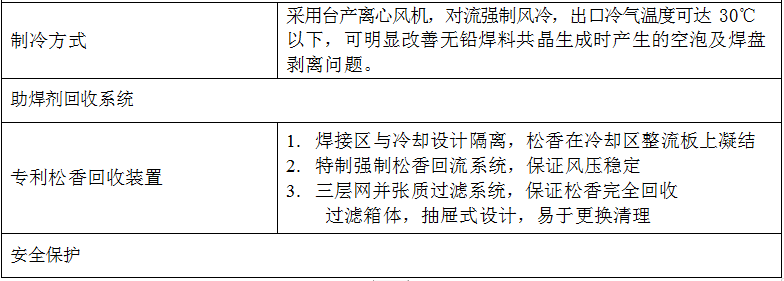

Cooling and convenient flux recovery system

1. The forced cooling system adopts two sections of forced air cooling temperature zone to meet the lead-free process; smooth cooling curve, no sudden change, full heat exchange, cooling rate is greater up to -5 ℃ / S.

2. Flux collection system can keep the furnace chamber clean for a long time, and the exhaust gas emission is more environmentally friendly. Nitrogen furnace after the separation of the gas can be recycled to save nitrogen.

3. Filterless design, very easy to clean.

Previous article:Practical eight temperature zone computer reflow soldering machine

next article:RF-8820PC-LF Lead-free Electric Control Eight Temperature Zone Hot Air Reflow Soldering

Related Products

-

Practical eight temperature zone computer reflow soldering machine

-

RF-8820PC-LF lead-free computer-controlled eight-temperature zone

-

RF-8820PC-LF Lead-free Electric Control Eight Temperature Zone Hot Air Reflow Soldering

-

RF-8810PC-LF lead-free computer-controlled eight-temperature zone hot air reflow soldering